Fillet Vs Chamfer: Ultimate Guide for Beginners

A fillet is a rounded corner that connects two surfaces. Chamfer is an angled edge that also does the same

No. 569 Jinbi Road, Pingshan Community, Biling Street, Pingshan District, Shenzhen City, Guangdong Province, China

Explore our core values and company events reflecting our dedication to excellence and innovation in CNC machining.

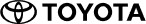

As an industry-leading CNC machining manufacturer, RongHua

machining provides all types of CNC machining services for your custom

projects.

RongHua Solution offers high-quality machined

components, innovative technologies, versatile manufacturing

capacities for large and low-volume orders, and favorable prices won

us, happy customers, worldwide with long-term cooperation.

Ronghua Solution offers a wide selection of materials and surface finishes to meet your demands for different industries. Check out the material options for your custom CNC machining parts.

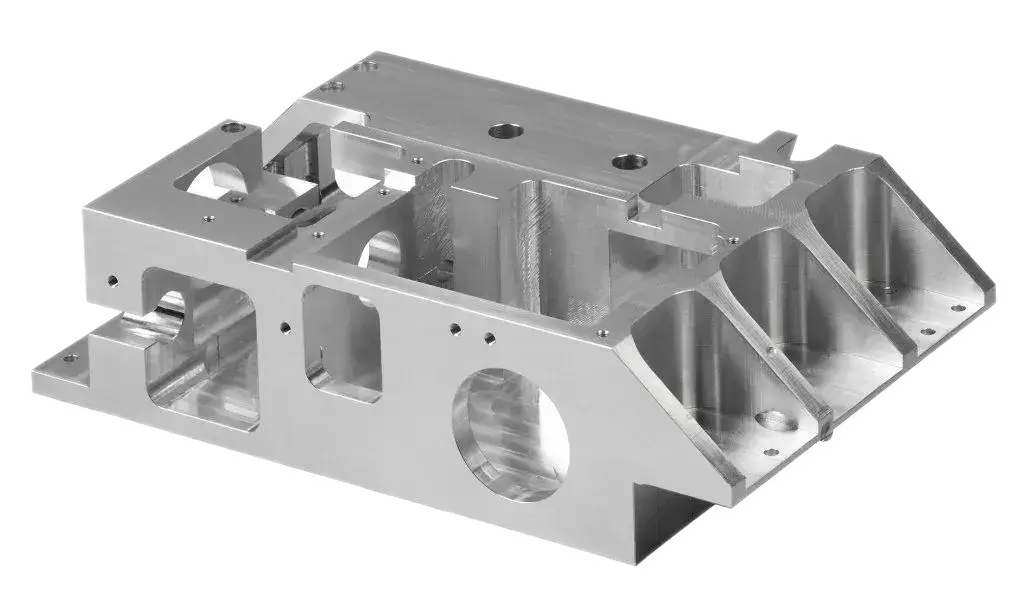

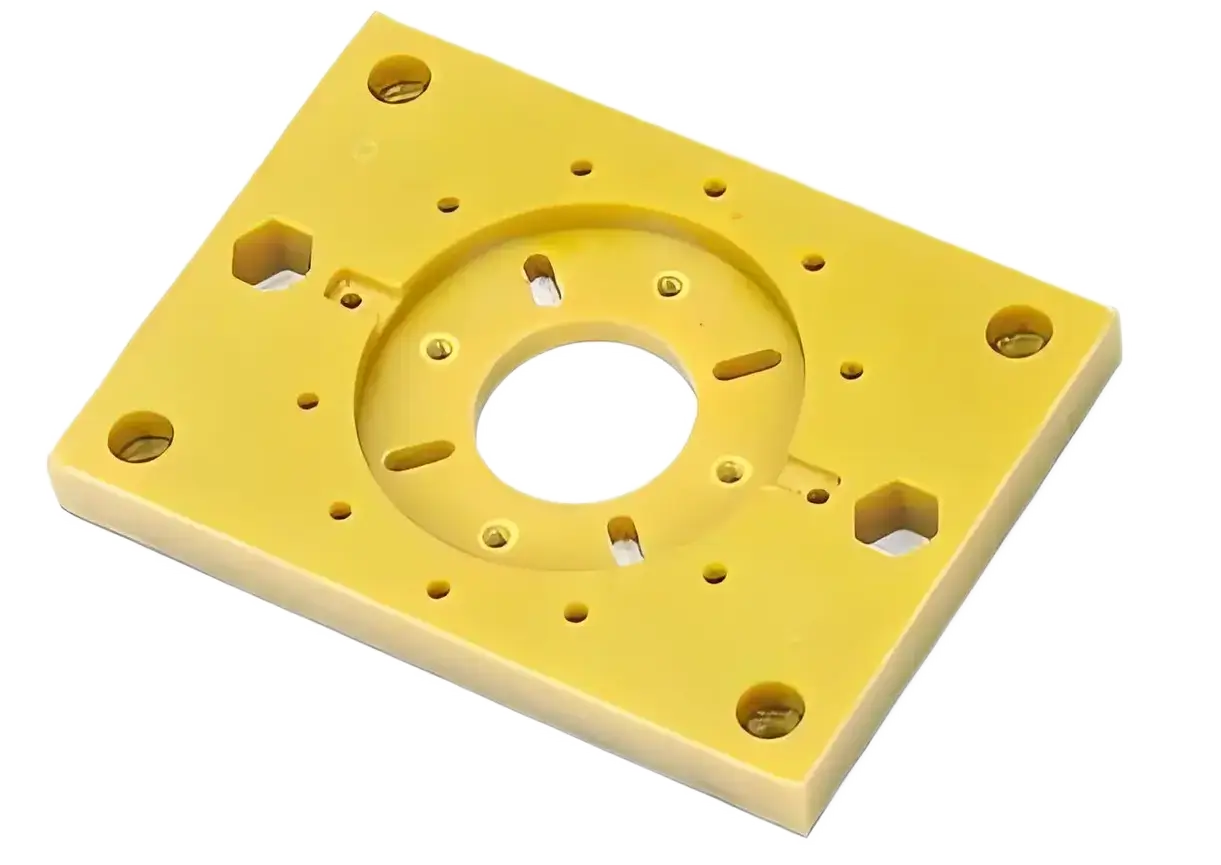

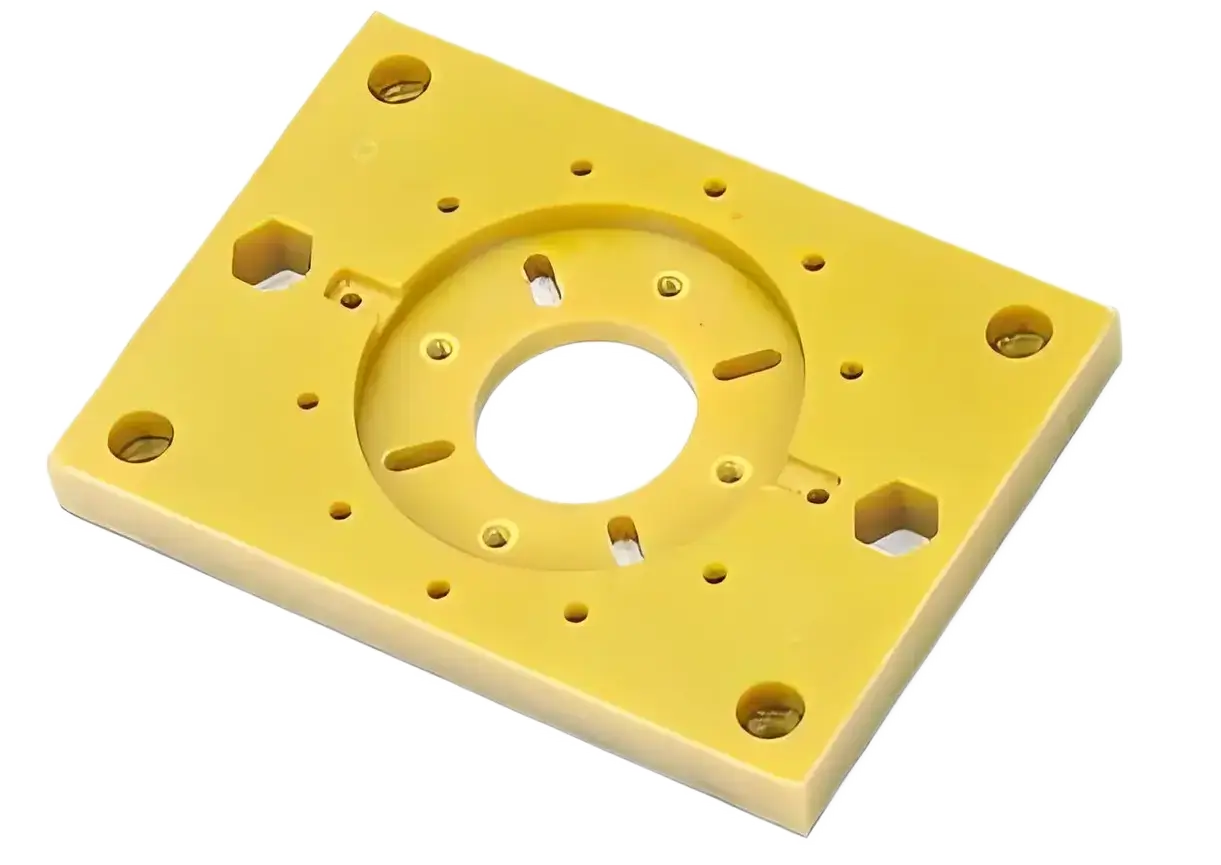

Get high-quality CNC milled parts from a wide selection of materials as your project requires at less cost. CNC milling services for both one-piece prototypes and production in large or small batches.

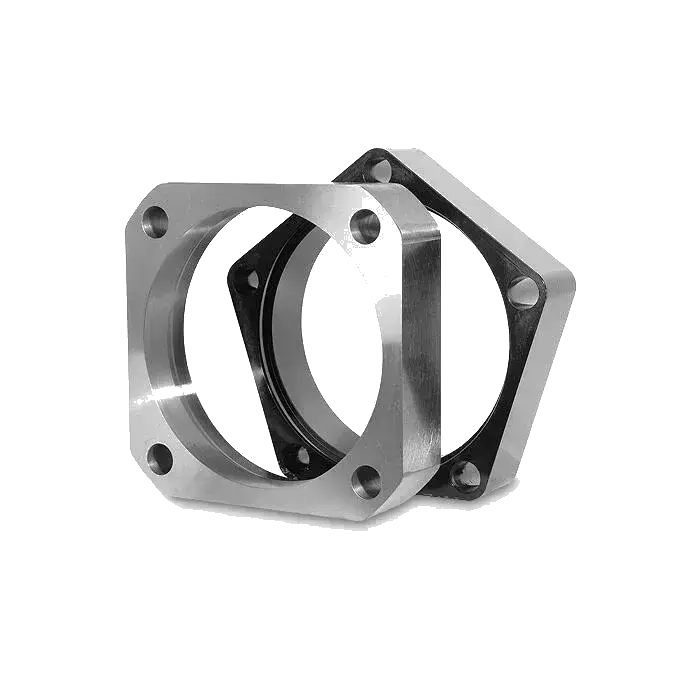

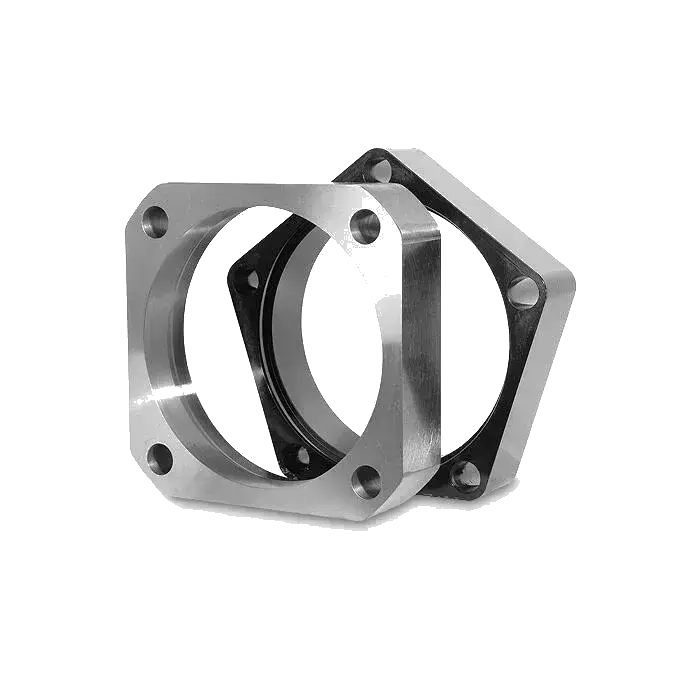

Ronghua machining provides high-quality and efficient CNC turning services with advanced production facilities, quick support, and competitive prices. Make sure you get top-notch CNC turned parts that meet your requirements from a reliable CNC machining manufacturer.

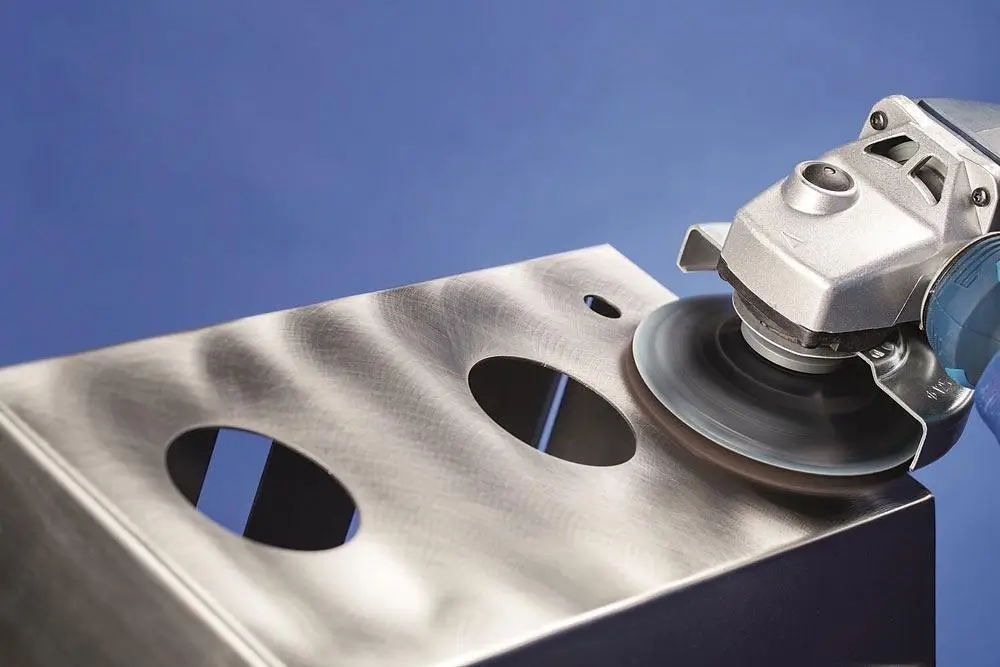

We provide many specialized procedures as part of our custom sheet metal fabrication services to fulfill your individual needs.

Standard and custom fastener solutions for industrial and commercial applications. Make custom screws, bolts, and nuts from a trusted CNC machining manufacturer for your unique projects with fast shipping and less cost.

Ronghua

machining has been devoted to the design, development, and

manufacturing of CNC machined parts for over 20 years with a wide

range of services including the production of milling parts, turning

parts, casting parts, sheet metal fabrication, and

fasteners.

Our powerful manufacturing capabilities in CNC

machining and skilled experts make

Ronghua machining a reliable choice

for your custom CNC products.

_r__1080-1218_c__b4b2ab_.png?x-oss-process=style/webp)

Have a design concept in mind? Ronghua machining is here to

bring your brilliantidea into reality.

No matter what

you need (prototypes or production parts, metal or

plasticmaterials), we will provide the best CNC

machining solution withprofessional production advice

and deliver parts that meet yourrequirements.

Here

are the top reasons why you should work with Ronghua

machining for custom CNC machining:

Our team of professional engineers and technicalexperts

has gained accumulated experience fromprevious works and

is able to answer all of yourmanufacturing

inquiries.

From CNc turning, and milling to stamping

and diecasting projects, we can provide support for all

types ofCNC machining services that help improve

efficiency andsave costs.

lf you have any special

requirements for your projectcontact us and we are ready

to help you with continuous support.

With an independent factory covering an area of over5000

square meters, Ronghua machining is capable ofmanufacturing

over 8 million pieces of parts andcomponents every

month.

For urgent orders, we can provide a

high-precisionsample within 24 hours.

lf a new mold

is required, we can provide the samplewithin 7 days

(with the new mold produced within 5days)

Combining

strong production capabilities withexperienced

engineers, Ronghua machining is sure to delivertop-quality

machining parts.

Compared with other CNC machining companies, Ronghua

machining is arecognized and trusted custom machining

parts partner in manyindustries around the world.

And

has established good strategic partnerships with a lot

of well-knowncompanies both in China and around the

world.

All of Ronghua machining equipment is imported from

Germany, SwitzerlandJapan, and Sweden.

With excellent

equipment, high-precision technologies,

exquisiteworkmanship, and strict quality

management,

Ronghua machining provides high-quality

machining products and professionaservices above the

international workshop level.

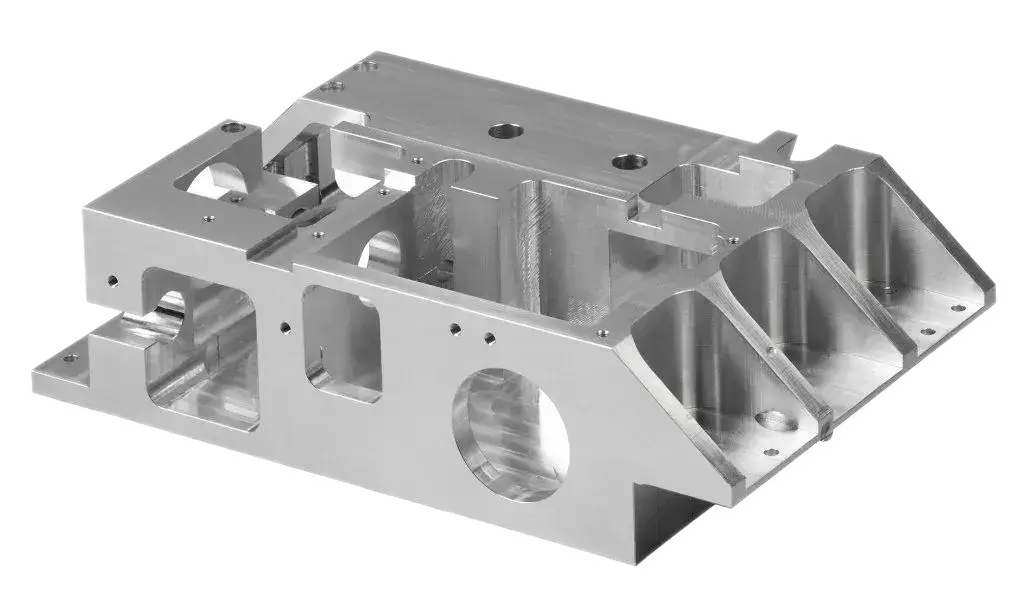

Ronghua machining Co, Ltd. has been delivering high-quality precision CNCmachined parts for over 20 vears with accumulated experience and clientsworldwide. From small-volume one-piece prototypes to large batch production, we canhelp produce CNC machining parts that meet your specific demands. Whether you are looking for parts with complex geometries or high-endsurface finishes, we will not let you down with our cutting-edge technologiesand extensive expertise in CNC machining.

With years of sales and production experience, our technical experts are ready to assist you with your unique CNC machining projects.

If you have any specific application in mind, we can advise you on the best solutions with professional tips on manufacturing techniques, materials, and surface finishes based on our understanding of relevant fields.

Ronghua Solution offers a wide selection of materials and surface finishes to meet your demands for different industries. Check out the material options for your custom CNC machining parts.

At Ronghua Solution, you can order CNC machining parts tailored to your needs in a straightforward process:

Ronghua machining is equipped with full and advanced production facilities to cater to your specific needs for custom CNC machining parts. The major equipment includes the following:

Generally, the CNC machining parts are processed through several standardized and strict steps:

The whole CNC machining process is under strict quality control. The quality of your CNC machined parts is ensured in a variety of ways:

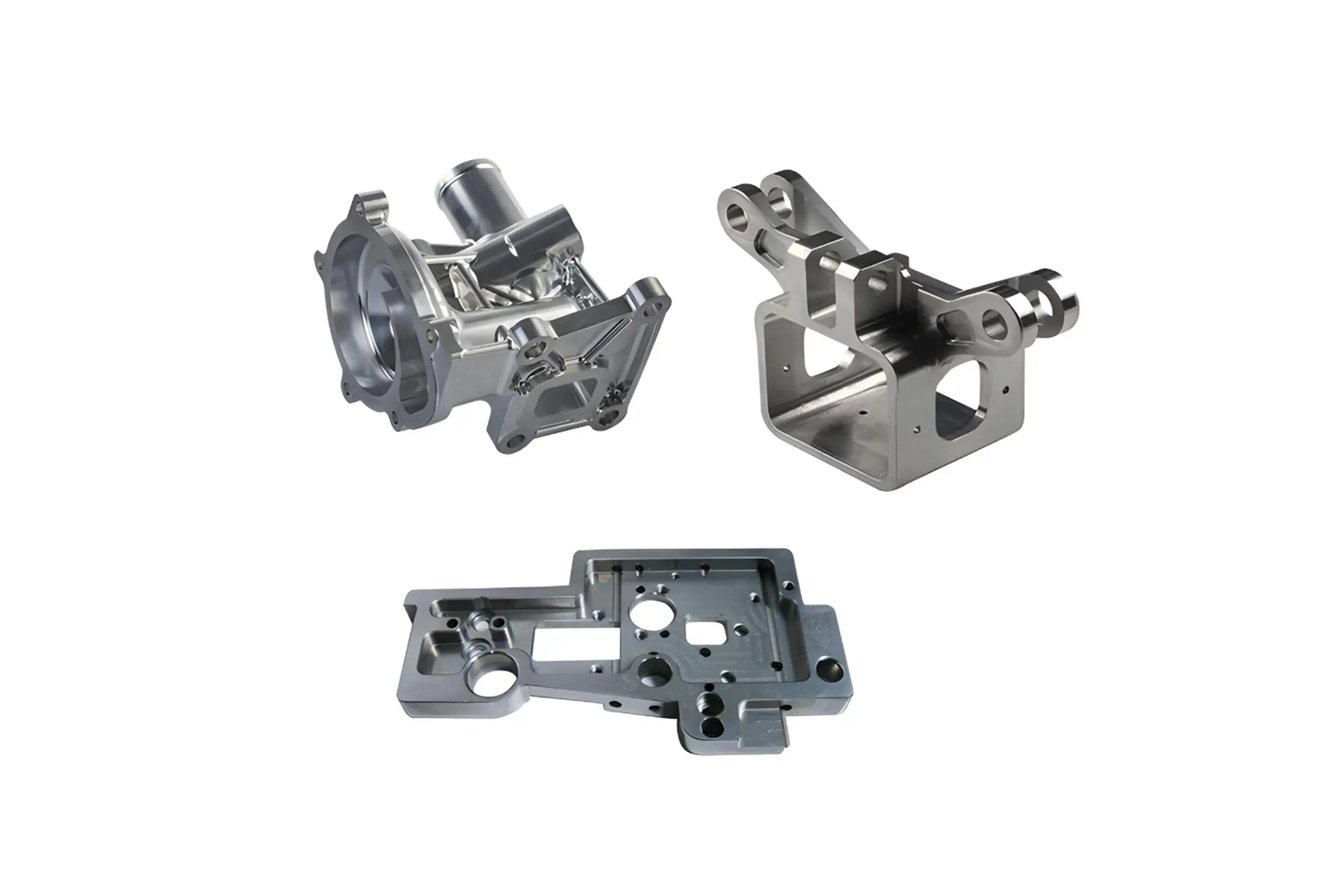

CNC machining technologies can be applied to a wide range of fields including the automotive, aerospace, consumer goods, medical, energy, optical communication, and robotics industries, etc.

We cater to the CNC machining needs in the automotive industry with the capacity of producing low-volume CNC parts and components.

Our precision CNC machined parts can meet the strict requirements of the aerospace industry with high quality and durability.

Ronghua Machining offers flexible manufacturing solutions to deliver CNC machining parts for the consumer goods industry, including houseware, electronics, cosmetic packaging, etc.

We produce high-precision CNC medical parts with either simple or complex geometries.

We are capable of making industrial-grade parts and components on a large scale efficiently to satisfy your needs for the robotics industry.

We offer high-precision semi-conductor at favorable prices from 7 top-notch manufacturers.

Ronghua Solution offers a wide selection of materials and surface finishes to meet your demands for different industries. Check out the material options for your custom CNC machining parts.

MAIN MATERIAL

CONTENT

Aluminum

A16061, A16063, A16082, A17075, Al2024, A15052, A380, etc.

Stainless Steel

55201, 55301, 55303, SS304, 55316, 55416, etc.

Steel

Mild Steel, Carbon Steel, 4140, 4340, Q235, Q34513, 20#, 45#, etc.

Brass

C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc.

Copper

C11000, C12000, C12200, C10100, etc.

Iron

20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc.

Plastic

POM, Peek, PMMA, ABS, Del Rin, Nylon, PVC, PP, PC, etc.

MAIN MATERIAL

CONTENT

Aluminum

Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, Power Coated, Nickel Plated Etc.

Stainless Steel

Brushed and Polishing, Passivating, Sandblasting, Laser Engraving, Gold Plating Etc.

Steel

Zinc Plating, Oxide Black, Nickel Plating, Chrome Plating, Carburized, Powder Coated.

Plastic

Plating Gold (ABS), Painting, Brushing (Acrylic), Laser Engraving.

Every customer’s evaluation is our goal of continuous improvement

CNC (Computer Numerical Control) services, also known as CNC machining services, are widely used in the manufacturing process across different industries.

An experienced operator usually uses a specialized machine tool to program a set of operations according to your part design.

The control system of the CNC machine allows the tool to perform the set operations and movements so that the final parts can meet your specific requirements.

The CNC machining cost depends on many factors and varies among different situations.

The material is a big factor. The machining difficulties can vary greatly depending on the materials you choose, which will affect the CNC machining cost.

The design complexity also makes a difference in the CNC machining cost.

It’s easy to understand that the more complex the design is, the more machining process is required and the higher the price will be.

Other factors such as market fluctuation and the order quantity can also affect the final quotation.

If you want to know the CNC machining cost for your project, send us a message and you will receive a quotation with manufacturing advice within 24 hours.

There is a wide range of CNC machining services. Ronghua machining covers the most popular types that can support most of your CNC machining designs and projects, including the following:

Other precision CNC machining services are also available on demand. Contact us to discuss details and get an instant quote.

CNC machining center is basically an automated machine tool with a programmed control system.

Based on the position of the spindle, CNC machining centers can be divided into vertical, horizontal, gantry, and universal types.

Vertical CNC Machining Center:

The vertical CNC machining center usually adopts the column structure in fixed positions and a rectangular worktable.

There are usually three linear motion coordinates (X, Y, and Z axes) on the worktable although a fourth axis (A) can also be installed.

The vertical CNC machining center has a compact and simple structure with a lower price tag.

It’s easy to operate, observe the operations during the machining process, and debug the program if anything goes wrong.

This type of machining center is suitable for creating plates, sleeves, and plate parts.

However, the large parts with tall height can not be handled with a vertical CNC machining center due to the column’s height restrictions and its tool change mechanism.

Horizontal CNC Machining Center:

The horizontal CNC machining center adopts movable columns and the headstock between the two columns moves up and down along the guide rail during the manufacturing process.

There are usually three motion directions: Axis X moves between the left and right sides, axis Z moves between front and back, and axis Z moves between the up and down.

A fourth axis A can also be installed on the worktable just like the vertical CNC machining center.

The horizontal CNC machining center is often used for manufacturing spiral wires and cylindrical cams.

It’s not that easy to observe the debug program, test the pin cutting, monitor the manufacturing process, and clamp and measure parts.

However, it’s easy to discharge pins during the process.

Compared with the vertical CNC machining center, the horizontal types feature a more complicated structure that takes up larger space and leads to a higher price.

Gantry CNC Machining Center:

In most cases, the gantry CNC machining center features a vertical spindle, an ATC system and replaceable spindle head accessories.

The system is very functional and can be used for multiple purposes with a single machine.

This type of CNC machining center is suitable for parts of large sizes.

Universal CNC Machining Center:

The universal CNC machining center is a five-sided machining center. It features the functions of both the vertical and horizontal CNC machining center types.

When a workpiece is clamped, all sides, excluding the mounting surface, can be completed at one time.

There are basically two types of universal CNC machining centers:

1) The one that can work as a vertical or horizontal CNC

machining center with the spindle being able to rotate

90°

2) The worktable rotates 90° with the workpiece

and the spindle remains in the same direction

Choosing a reliable CNC machining manufacturer is crucial to get high-quality parts as desired.

There are several things you need to take into consideration when searching for the best CNC machining service provider:

1. Reputation

A good reputation means the CNC machining company is striving for customer satisfaction with quality products and after-sales service.

Always check out the comments from its previous customers to decide whether to work with the CNC machining service provider.

2. Product Quality

The quality of CNC machining parts is the top consideration for your purchase.

A reliable CNC machining manufacturer should listen to customers’ voices and produce the parts strictly according to the client’s requirements.

At Ronghua machining, you can even configure the models and the guide rails to meet your specific accuracy requirements.

3. After-Sales Service

Good after-sales service doesn’t mean the products are problematic. It shows that the CNC machining manufacturer is reliable, so you can always find support if anything goes wrong.

Ronghua machining has a very efficient and professional after-sales team that handles your issues in a timely manner.

Besides that, a follow-up is carried out after purchase and service to make sure you are satisfied with the CNC machining parts.

4. Qualitifications & Certifications

There are a lot of CNC machining manufacturers on the Internet and the information can be dazzling.

Be sure to check out their qualifications and certifications (preferably revealed by third parties) before you place the order.

If you are shopping online, pay attention to the store’s rate, customer reviews, and the age of the store, which greatly reflects whether the CNC machining supplier can be trusted or not.

Choosing a satisfying CNC machining service provider requires extensive research and comparison.

If it’s possible, you can make a field trip to select the best company for your project.

We offer fast and cost-effective CNC machining solutions.

Get high-quality parts for your CNC machining projects with fast turnaround times, following your design specifications.

A fillet is a rounded corner that connects two surfaces. Chamfer is an angled edge that also does the same

Are you looking for a complete understanding of brushing surface finishing tools, techniques and best practices? This ultimate guide contains

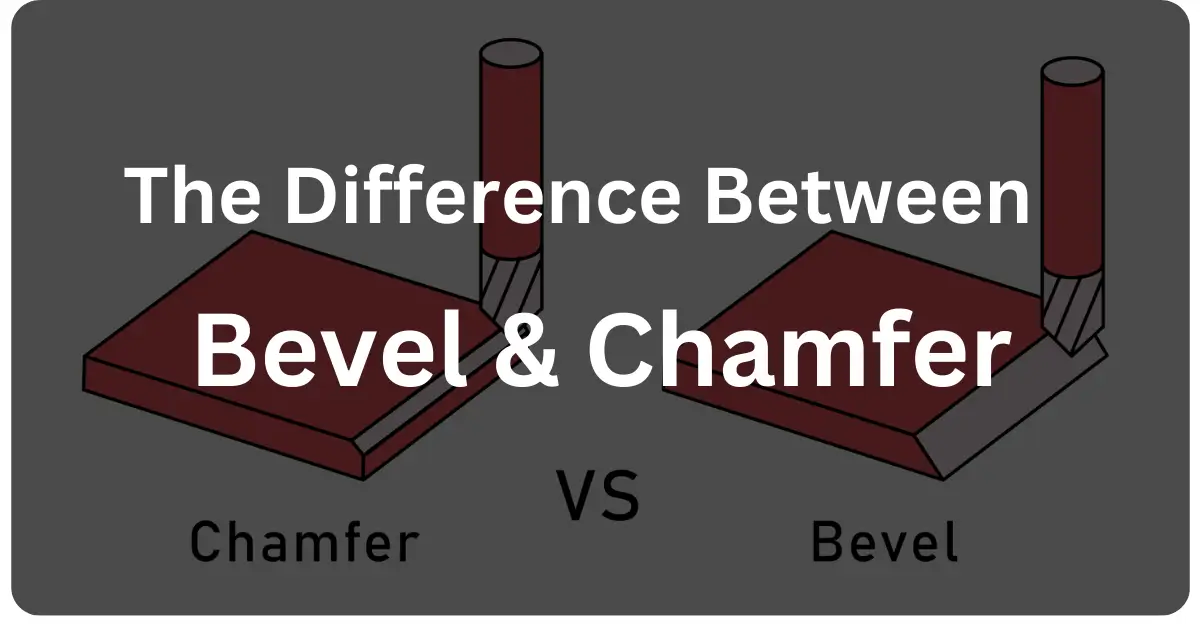

Bevel and chamfer are used for edge treatments. Edge treatments play a decisive role in customizing the sharp corners of

Free Machined Parts Design to Your Projects with Fast Turnaround Times.

Quick links

Contact

© 2024 Shenzhen Ronghua Machining Co., Ltd, All rights reserved