What is CNC Programming? | Code Types, Methods & Tips

What is CNC Programming? CNC programming involves creating a detailed set of instructions for a CNC machine to follow in

No. 569 Jinbi Road, Pingshan Community, Biling Street, Pingshan District, Shenzhen City, Guangdong Province, China

Explore our core values and company events reflecting our dedication to excellence and innovation in CNC machining.

Ronghua machining offers reliable CNC milling services for customers worldwide, providing rapid prototypes and production parts with tight tolerances, high accuracy, and various materials available.

Find high-precision, cost-effective, and top-notch custom CNC milling parts at Ronghua machining that meet the strict needs of different industries.

Take a look at our gallery of custom CNC milling parts and discover the different CNC milling samples we’ve worked on for a wide range of clients.

CNC milling parts are produced by rotating the cutting tools to remove material from the workpiece while the workpiece itself remains stationary.

CNC milling is one of the most widely used machining processes due to the following advantages:

Is CNC Milling Suitable for Your Project? CNC milling parts are very common these days with CNC milling services becoming popular in various commercial and industrial applications.

Traditional milling machines can cause big errors due to manual operation, while CNC milling parts can guarantee high standard accuracy and surface roughness thanks to its computerized control.

CNC milling can handle more complex structures that are not possible with traditional milling machines, especially the parts that are difficult to observe and control, such as the custom mechanical parts.

CNC milling service is usually preferred for machining custom parts with irregular or curved profiles to various degrees, and the whole process is automated.

Thanks to the versatility of the CNC milling machines, the CNC milling parts are widely used in the following fields:

Whether you need rapid prototypes, CNC-milled parts in small batches, or custom parts for mass production.

Ronghua machining can provide you with the best CNC milling service that meets your high standards from production to delivery.

Ronghua machining is equipped with state-of-art CNC milling machines to produce high-quality milled parts. Featuring three-, four- and five-axis advanced milling machine centers, we can handle all kinds of complex CNC milling parts to satisfy the strict requirements of different industries.

Ronghua machining, as an industry-leading CNC milling parts manufacturer, has over 20 years of experience in the production of high-precision CNC milled parts. With our experienced engineers and in-house machining team, you will be sure to receive high-quality CNC milling parts with fast lead time.

Ronghua machining is ISO 9001: 2015 certified. Our QC and QA teams are professionally trained and will monitor the whole CNC milling process from beginning to finish to ensure your milling parts meet the finest quality specifications.

Working with an efficient CNC milling parts company saves a lot of time and cost. At Ronghua machining, your custom CNC milling parts can be made within hours. Send us a message, and you will get a quick quotation in 24 hours to kick off your project.

Ronghua machining provides various surface finishing options to improve the appearance of your custom-milled parts, including grounding, sandblasting, and electroplating.

We can produce high-precision, complex-shaped CNC milling parts that fully comply with your design specifications, critical tolerances, and manufacturing guidelines.

Find quick answers to questions about CNC turning and Ronghua as a top CNC turning part supplier.

What does CNC machining stand for?

CNC is shortened form of Computerized Numerical Control. In short, the CNC milling service basically involves the machining process that uses a rotating tool to remove the material of a workpiece until the desired shape is achieved.

How does CNC milling work?

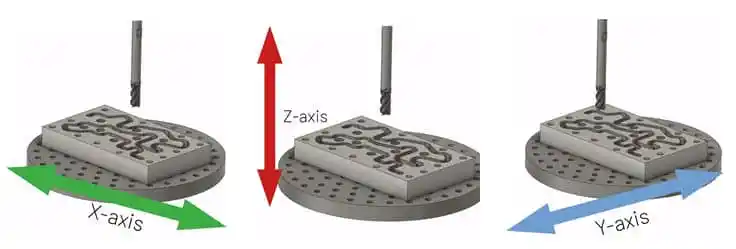

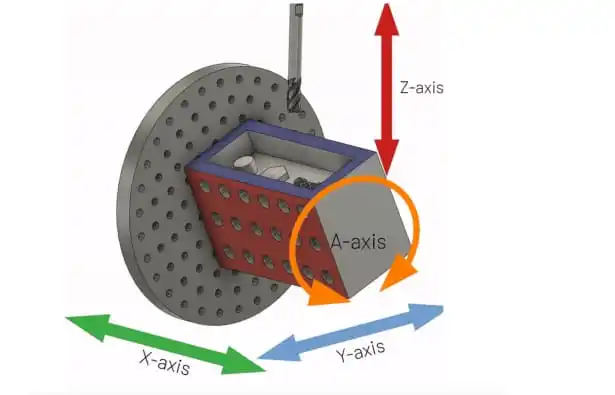

During the process, the raw materials are fixed in place on a CNC worktable which can move on different planes and axes (up to 5 axes, typically in X, Y, and Z axes) so the cutting tool can work at multiple angles.

The rotating tool spindle at a very high speed to cut the material and achieve the desired finished part.

CNC machining is one of the most common and basic mechanical manufacturing processes due to its high accuracy, precision and tight tolerance (down to +-0.001mm) for creating complex specifications of your custom parts.

The best part of precision CNC milling service is its capability to produce complex shapes and precision parts with tight tolerance throughout the process, whether in small or large batches.

The number of axes implies the complexity of the movements of the workpiece and cutting tool compared to each other.

Simply put, 5-axis machines can produce CNC mill parts with more complex geometry compared with the others.

As a professional CNC milling parts manufacturer, Ronghua machining has adopted a comprehensive quality control system to ensure your part quality, from communication to production and inspection.

The tolerance of CNC-milled parts depends on many factors, including (but not limited to) part sizes, the complexity of your design, materials, and surface finishes.

There is no specific number that suits all types of design.

At Ronghua machining, our standard tolerances for CNC-milled parts range from ± 0.10mm to ± 0.05mm.

For the unmarked linear tolerance of CNC machined parts, we comply with the standard of ISO 2768.

A tighter tolerance is also possible for your custom-milled parts. Send us a message and discuss the customized CNC service required with our engineers.

Yes, we can provide the OQC report (and material report, inspection report, compliance certificates, etc) upon your request.

Please make sure to ask for it before you place/confirm the order.

Otherwise, we may not be able to provide some of the required information, such as material reports.

You will receive a quick quotation in 3-5 hours on work days after sending your design file with detailed specifications, sizes, and quantities. 24/7 support all year round.

You rest assured to get high-quality CNC milling parts as desired with our careful drawing checks and strict quality inspections.

Choose from over 30 kinds of metal and plastic materials. Ronghua machining offers a wide variety of certified materials for your custom milling parts.

You will receive a quick quotation in 3-5 hours on work days after sending your design file with detailed specifications, sizes, and quantities. 24/7 support all year round.

Your ordered parts can be finished as fast as one day and shipped to you right away. Ronghua machining features advanced technologies to accelerate production.

No minimum order quantity is required. One-piece prototypes, low-volume manufacturing or mass production at the most competitive price.

What is CNC Programming? CNC programming involves creating a detailed set of instructions for a CNC machine to follow in

What is M Code? M code, short for Miscellaneous code, is an essential component of CNC (Computer Numerical Control) programming.

This article aims to demystify CNC fixtures, exploring their types, components, and the critical considerations in their design. What is

Free Machined Parts Design to Your Projects with Fast Turnaround Times.

Quick links

Contact

© 2024 Shenzhen Ronghua Machining Co., Ltd, All rights reserved